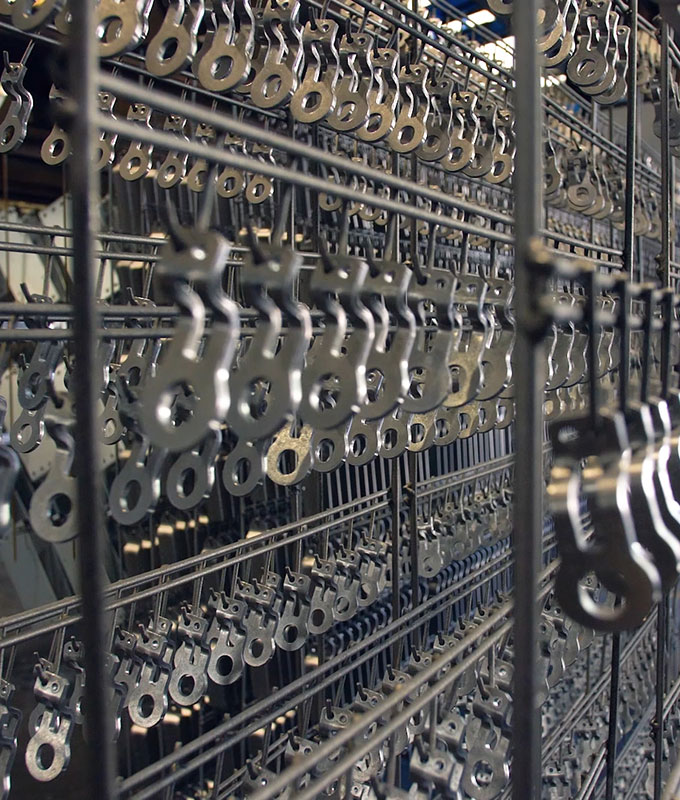

Since 2009 (year of foundation of the company) cataforesi srl has been supporting small and large companies, operating in various sectors, offering quality painting services.

Attention to detail, professionalism and punctuality in the services offered have allowed cataforesi srl to become a point of reference for the most prestigious car manufacturers in the world and for the automotive sector in general.

CATAFORESI

FIELDS OF COMPETENCE

Since the company’s founding, the field in which Cataforesi has operated is mainly the automotive sector in all its forms (cars, motorcycles, cycles, trucks, rail vehicles, boats…) dealing with components made of iron, steel, aluminum and other conductive materials.

Other sectors that occupy an important percentage of our production are:

– Construction (street furniture, lighting, in general material intended for the external environment)

– Agriculture

– Railway (railway vehicles in general)

– Naval

– Minuteria painting

CONTINUOUS EVOLUTION

Each phase of the treatments is managed according to the highest standards offered by the technology and know-how available on the reference market.

Research and development are an integral part of the company’s activity and guarantee the use of the best treatment to offer our customers based on the materials, structure and shape of the objects to be treated.

ADVANCED LOGISTICS

An effective painting process cannot ignore a structured management of the different types of plant necessary for the treatment.

We take great care in managing orders, from their receipt to the return of the processed materials to the customer.

Personalized logistics service throughout northern Italy.

LEAD TIME

Standard processing and delivery times are approximately 2/3 working days from the date of receipt of the material.

MASKING

Cataforesi Srl also offers a masking service for any areas that need to be preserved from any surface treatments through the use of conical plugs (for holes) and adhesive tapes resistant to high temperatures (it is possible to produce them with specific shapes and dimensions)

CERTIFIED PROCESSES

Certified according to ISO 9001:2015, Cataforesi Srl manages each process with specific procedures.

The primary objectives are the efficiency and quality of the service as well as customer satisfaction.

Our processes meet the requirements of the specifications of the main automotive manufacturers worldwide.

ENVIRONMENTAL RESPECT

The quality of a painting process is also guaranteed with the adoption of correct standards and practices in managing the recovery of substances used with advanced purification systems and using chemical components with the lowest possible environmental impact.

We operate in compliance with environmental regulations by subjecting our plants to rigorous periodic checks and using purification systems that respect the environment beyond what is required by law.

Starting from July 2022, a photovoltaic system has also been installed aimed at reducing the use of fossil fuels.

RATING ESG

From the beginning of 2024 Cataforesi SRL has undertaken a study on its sustainability divided into the following 3 areas:

•Environmental

• Social

• Corporate governance

which allowed it to achieve the ESG sustainability rating.

Environmental factors concern the need to favor less energy-intensive production processes and with less impact on the environment; social sustainability factors refer to working relationships, inclusion, community well-being as well as respect for human rights; finally, corporate governance factors concern compliance with diversity policies in the composition of company management bodies, the presence of independent directors or the methods of remuneration of managers, elements which have a central role in ensuring that social aspects and environmental issues are considered in the decisions of businesses and organizations.

Environmental, social and corporate governance factors are essential to qualify an activity as sustainable.

LEGAL RATING

On 18 April 2024 Cataforesi SRL obtained the legality rating, a certification that guarantees the company’s possession of high standards of compliance with the law and social responsibility.

This certificate has become an extremely important element for operating in the markets as it also contributes to determining the company’s reputation and health and guarantees the regularity of payments of pension and insurance contributions to third parties.

The Antitrust Authority has defined the acquisition of this rating as a reward for “business management based on ethics and legality”

CONTINUOUS INVESTMENT, BY CHOICE AND BY CONVICTION

Cataforesi Srl cooperates with the main manufacturers of paints and chemical products on the market and uses eco-sustainable products.

With constant and careful commitment to respecting the environment, it makes use of the collaboration of authorized, certified and selected companies for their proven reliability, competence and technical support, for the collection and disposal of waste and for the purification and regeneration of water.

DISCOVER CATAFORESI SRL